Just in Time (Cambridge (CIE) A Level Business): Revision Note

Exam code: 9609

Just in Time versus Just in Case

1. The just-in-time approach (JIT)

The just-in-time (JIT) approach involves raw materials and components being ordered as required and delivered "just in time" to be used in production

Raw materials and components are ordered from a small number of trusted key suppliers just before they are to be used

Close, long-term relationships with these suppliers need to be developed

Many businesses using JIT inventory management systems aim to source raw materials and components from local or regional suppliers

They must be flexible and reliable

They may be required to hold inventory on behalf of a JIT-operating customer

They are often in close proximity to their key JIT-operating customer

Evaluating the just-in-time approach

Advantages | Disadvantages |

|---|---|

|

|

Examiner Tips and Tricks

When you explain the JIT approach, link every benefit (less inventory, lower storage costs) to a risk (stockouts if deliveries slip)

Showing both sides proves you understand why lean systems boost profit only when suppliers are rock‑solid

2. The just-in-case approach

Just-in-case inventory management involves a business holding a quantity of raw materials, components or finished goods as buffer stock

Stock is held in case of shortages so as to provide a competitive edge over rivals unable to meet demand

The decision to keep buffer stocks is one that businesses have to weigh up very carefully

Holding inventory incurs storage and security costs and can increase waste, as stock could be damaged, stolen or become obsolete

Failing to hold enough inventory could mean a business is unable to meet demand, potentially missing out on sales revenue

Evaluating the just-in-case approach

Advantages | Disadvantages |

|---|---|

|

|

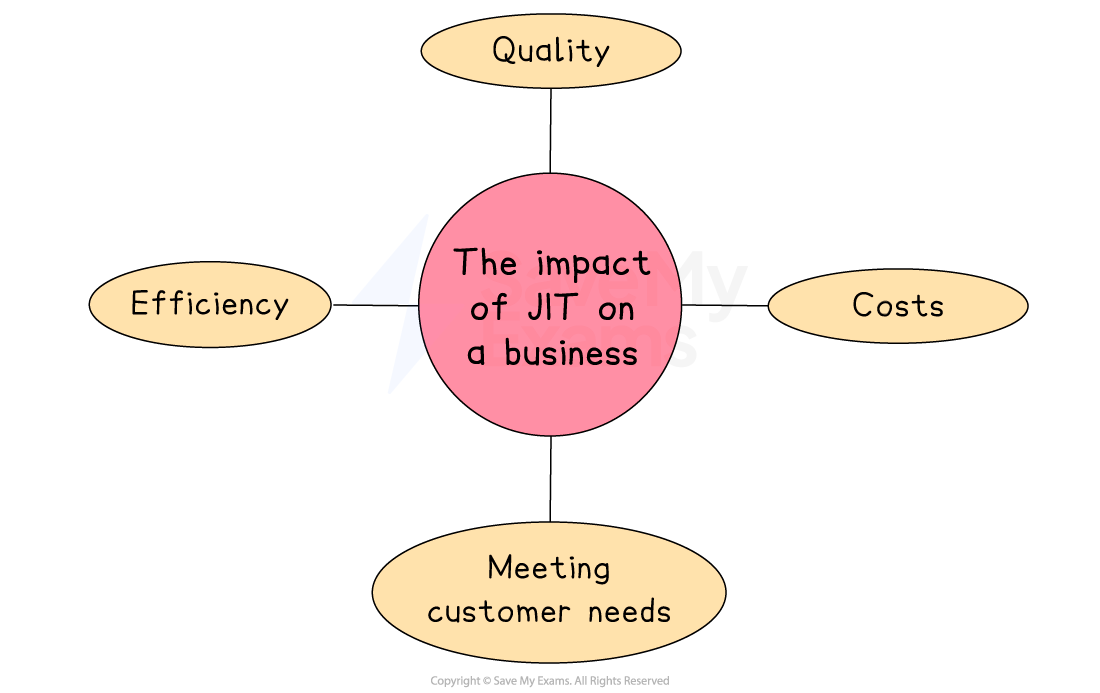

The impact of adopting a JIT approach

The JIT approach has significant effects on several areas of a business

Impact on costs

Lower inventory costs

Since stock is only ordered when needed, businesses spend less on storage facilities and insurance

Less money tied up in stock

Firms have more working capital available for other uses, like marketing or staff training

Fewer waste costs

JIT reduces the risk of obsolete or damaged stock, especially for perishable or seasonal items

Impact on quality

Improved supplier quality

Businesses work closely with reliable suppliers to ensure materials meet high quality standards

Faster feedback loops

Any quality issues are noticed and fixed quickly, as production is continuous and lean

Focus on right-first-time

As there’s no buffer stock, production teams must work efficiently and avoid errors

Impact on efficiency

Streamlined production

JIT promotes smoother workflows and reduces idle time between stages of production

Motivated workforce

Workers often have more responsibility and take part in continuous improvement (Kaizen)

Space-saving

With fewer storage needs, factory space is better used for production activities

Impact on meeting customer needs

Faster response to changes

Businesses can adapt quickly to shifts in consumer demand, reducing the risk of overproducing unpopular products

Customisation

JIT allows more flexible and tailored production, often linked to modern mass customisation systems.

Freshness and quality

Products are made closer to the time of sale, especially useful in food and fashion industries

Unlock more, it's free!

Was this revision note helpful?