Methods of Inventory Management (Cambridge (CIE) A Level Business): Revision Note

Exam code: 9609

The purpose of inventory

Inventory is the goods and materials a business holds for the ultimate goal of resale or for use in production

Types of inventory

Raw materials | Components |

|---|---|

|

|

Work-in-progress | Finished goods |

|

|

Costs and benefits of holding inventory

The management of stock is an important consideration for businesses

Problems may arise from holding inventory

Storage costs (e.g. warehouse rental, security costs) will be higher than necessary

The risk of spoilage and stock shrinkage is increased, leading to increased costs

Money tied up in stock could be used elsewhere in the business

Time and resources are needed to monitor and track stock levels

However, if a business holds inventory, it means that

Products are available when needed, improving customer satisfaction

Buying quantities of inventory and storing it may reduce unit costs due to bulk buying discounts

Production isn't held up by supply issues

Extra stock helps meet peaks in sales, such as during holiday periods

The importance of supply chain management

The supply chain is the network of organisations, people, activities and resources that move a product from its basic raw material right through to the final customer

It includes the following:

Stock control: planning, implementing and monitoring the movement of raw materials, components, work-in-progress and finished goods

Quality control: ensuring output meets standards so that the end product is safe and meets customer expectations

Transport networks: ensuring efficient deliveries of goods to customers, taking account of speed, reliability and costs

Supplier networks: developing strong relationships with suppliers willing to work collaboratively to improve quality

Global supply chains require these activities to be coordinated across international borders

Some stages can be completed at lower cost in certain countries

E.g. China has a reputation for producing high quality, low-cost electronics components

Labour-intensive processing, such as clothes manufacturing, is outsourced to countries with low labour costs, such as Vietnam

Scarce raw materials may only be available in certain countries/regions

Building an effective supply chain

Decision area | What it involves |

|---|---|

Make or buy (produce in-house or outsource) |

|

Choosing suppliers |

|

Purchasing approach |

|

Information sharing and use of technology |

|

Logistics structure |

|

Why does an effective supply chain matter?

Faster delivery to customers

When every link is well-coordinated, products move quickly from factory to shelf, beating slower rivals

Lower operating costs

Just-in-time (JIT) deliveries and bulk purchasing agreements reduce storage, handling and material expenses

E.g. Aldi negotiates long-term contracts with a small group of trusted suppliers, helping it minimise warehouse inventory and keep prices low

Consistent quality

Close, long-term relationships with suppliers make it easier to enforce standards and fix problems early

Greater resilience to shocks

A well-planned supply chain includes backup suppliers and effective data sharing so the business can adapt when something goes wrong

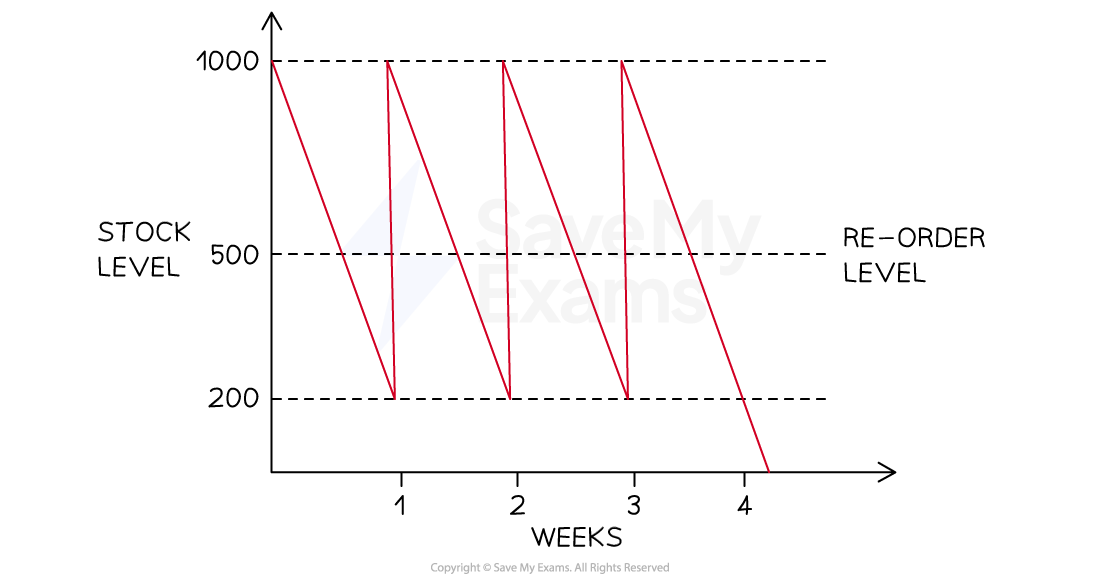

Inventory control charts

An inventory control diagram shows how inventory moves into and out of a business over time

An inventory control diagram

The maximum inventory level is the maximum amount of stock a business is able to hold in normal circumstances (1,600)

The reorder level is the level at which a business places a new order with its supplier (800)

The minimum stock level is also known as the buffer inventory level and is the lowest level to which a business is willing to allow inventory levels to fall (400)

Lead time is the length of time from the point of inventory being ordered from the supplier to it being delivered (one week)

The stock level line shows how inventory levels change over the given time period

As inventory is used up, a downwards slope is plotted

When an order is delivered by a supplier, the stock level line shoots upwards

Worked Example

The diagram below shows inventory movements of kitchen shelving units sold by TamFix Limited.

Identify the following points:

The minimum stock level

The reorder level

The reorder quantity

The lead time for kitchen shelving units

(4)

Answer:

Step 1: Identify the minimum stock level

The minimum stock level is identified by the bottommost dotted line

In this case, it shows that the minimum stock level is 200 units (1)

Step 2: Identify the reorder level

The reorder level is clearly identified on the diagram

In this case, it shows that the reorder level is 500 units (1)

Step 3: Identify the reorder quantity

The reorder quantity is the difference between the maximum stock level (shown by the topmost dotted line) and the minimum stock level

The reorder quantity is, therefore, 800 units (1)

Step 4: Identify the lead time for kitchen shelving units

The lead time is the difference in time between the time an order is placed and the time the inventory is delivered

In this case, assuming a five-day working week, the lead time for shelving units is two days (1)

Examiner Tips and Tricks

Always clearly label lead time, reorder level and buffer stock, and include units

Show your workings — examiners award method marks even if the final figure is wrong

Buffer inventory

Buffer inventory is a quantity of stock kept in case of shortages

This can provide a competitive edge over rivals unable to meet demand

This approach is commonly called ‘just in case’ stock control

The decision to keep buffer stocks is one that businesses have to weigh up very carefully

The decision will be influenced by the nature of the business and the product/service it provides

Evaluating the use of buffer stocks

Advantages | Disadvantages |

|---|---|

|

|

Unlock more, it's free!

Was this revision note helpful?