Lean Production (Cambridge (CIE) A Level Business): Revision Note

Exam code: 9609

The aims and purposes of lean production

Lean production is a management philosophy that aims to maximise value while minimising waste

It focuses on maximising efficiency, improving quality and reducing costs

Lean production is likely to lead to a competitive advantage

Lower unit costs are achieved due to minimal wastage so prices may be lower than those offered by competitors

Better quality of output is likely as a result of supplier reliability and carefully managed production processes

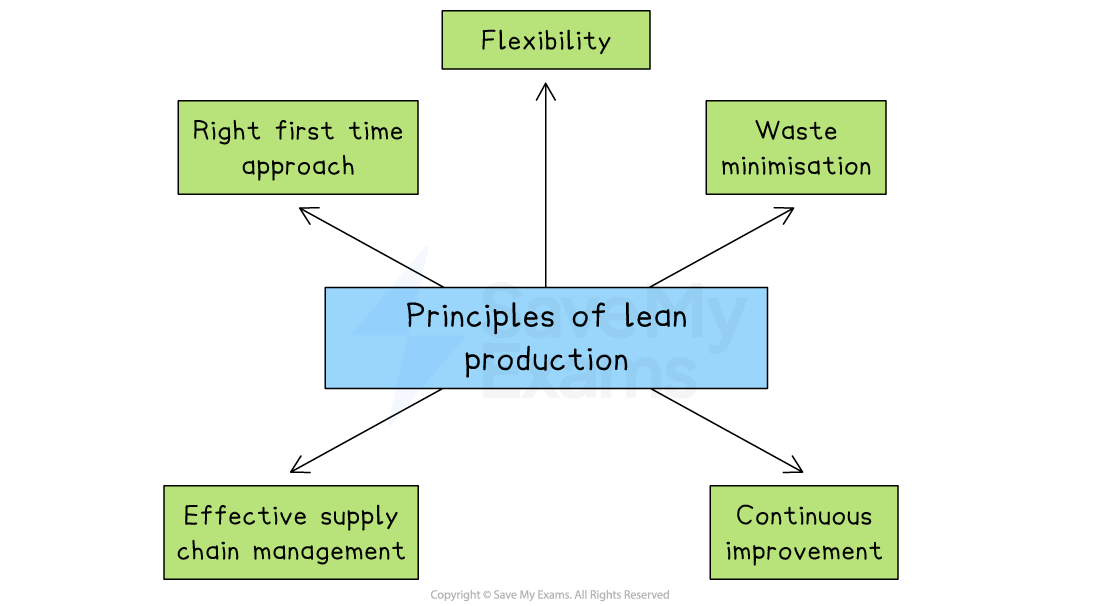

The main principles of lean production

Right first time approach

Aim for zero defects in output

Identify and solve problems as they arise

Prevent rather than correct errors

Flexibility

Adaptable capital equipment and physical resources

Multiskilled staff and team working

Flexible management styles

Waste minimisation

Remove processes that do not contribute to added value

Consume as little as is necessary

Rework rather than replace

Effective supply chain management

Develop excellent relationships with suppliers

Minimal number of suppliers

Continuous improvement

Ongoing, small steps

All staff involved in improvement

Lean production strategies

Businesses that pursue lean production can adopt a range of strategies

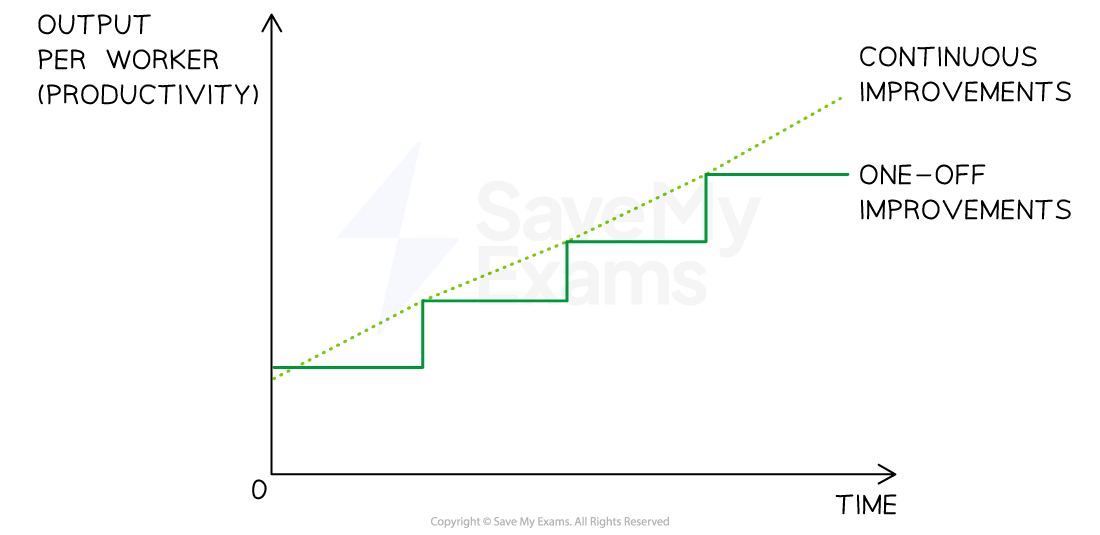

1. Kaizen

Kaizen means “continuous improvement” in Japanese

It involves small, regular changes made by employees at all levels

Workers are encouraged to suggest ways to improve efficiency, quality and processes

These ideas are implemented gradually over time

A comparison of Kaizen with one-off improvements

Evaluating the use of Kaizen

Advantages | Disadvantages |

|---|---|

|

|

2. Quality circles

Small groups of employees who meet regularly to discuss work-related problems and suggest improvements

These groups usually focus on improving quality, safety or productivity and include workers from different levels of the business

Evaluating the use of quality circles

Advantages | Disadvantages |

|---|---|

|

|

3. Simultaneous engineering

A production method where product development stages happen at the same time, rather than one after another

For example, design, engineering and marketing teams work together to reduce the time it takes to launch a new product

Evaluating the use of simultaneous engineering

Advantages | Disadvantages |

|---|---|

|

|

4. Cell production

A method of organising production into small teams that complete a whole part of the product process

Instead of passing work along a production line, each cell is responsible for a complete unit of work, encouraging ownership and teamwork

Evaluating the use of cell production

Advantages | Disadvantages |

|---|---|

|

|

5. Just-in-time manufacturing

Where products are made only when there is demand, and each stage of production begins only when needed by the next stage

This approach aims to match production with customer demand

This minimises waste, speeds up workflows, and reduces the need for warehousing

Evaluating the use of just-in-time manufacturing

Advantages | Disadvantages |

|---|---|

|

|

6. Waste management

Waste can be anything that does not add value, such as overproduction, excess inventory, delays or defects

Lean waste management aims to simplify processes and reduce costs

Evaluating the use of waste management

Advantages | Disadvantages |

|---|---|

|

|

The impact of lean production

Lean production affects not only how goods are made but also how people work, how quality is maintained and how inventoryis managed

Lean production impacts

Area of Impact | Explanation |

|---|---|

Inventory Control |

|

Quality |

|

Employee roles |

|

Capacity management |

|

Efficiency |

|

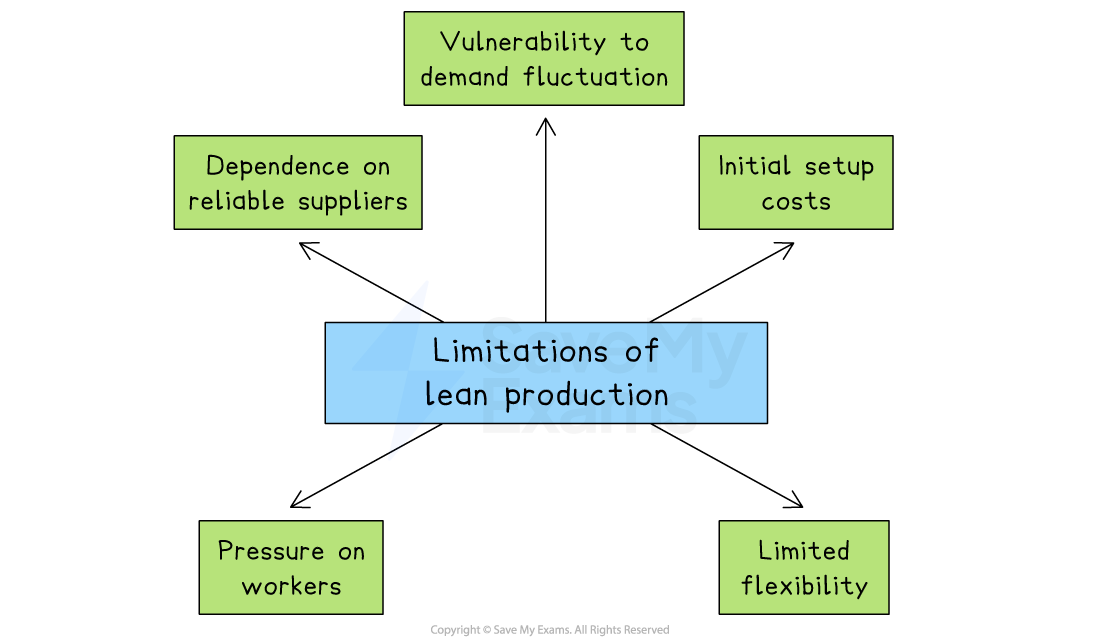

Limitations of lean production strategies

Lean production can improve efficiency and reduce waste, but it also presents several challenges and limitations that businesses must carefully manage

Dependence on reliable suppliers

Lean production often relies on just-in-time delivery

If suppliers are late or unreliable, production may stop entirely because there is little or no stock available

Vulnerability to demand fluctuations

Lean systems produce only what is needed

This makes it difficult to respond quickly to unexpected increases in customer demand, which can result in missed sales and unhappy customers

Initial setup costs

Introducing lean production may require investment in new equipment, staff training, and redesigning production processes

These upfront costs can be very high, especially for small businesses

Pressure on workers

Lean production gives employees more responsibility and expects constant improvement

This can create stress or lower morale if staff feel overloaded or too closely monitored

Limited flexibility

Lean strategies work best in high-volume, predictable environments

They are unlikely to be suitable for businesses with highly customised products or irregular demand

Unlock more, it's free!

Was this revision note helpful?