The Importance of Capacity, Efficiency and Productivity (AQA A Level Business): Revision Note

Exam code: 7132

Using capacity efficiently

Efficiency means producing with the fewest possible resources

Using less time, labour, materials or energy

Why efficiency matters

Lower costs per unit

Spending less on inputs increases profit margins or allows lower selling prices to compete better with rivals

Higher competitiveness

Efficient firms can respond quickly to orders, which attracts and retains customers

Better use of resources

Cutting waste frees up cash and reduces a business's environmental impact, meeting both financial and sustainability objectives

Ways to use capacity efficiently

Way | Explanation | Example |

|---|---|---|

Streamline the workflow |

|

|

Invest in automation |

|

|

Train staff |

|

|

Introduce just-in-time (JIT) inventory management |

|

|

Preventive maintenance |

|

|

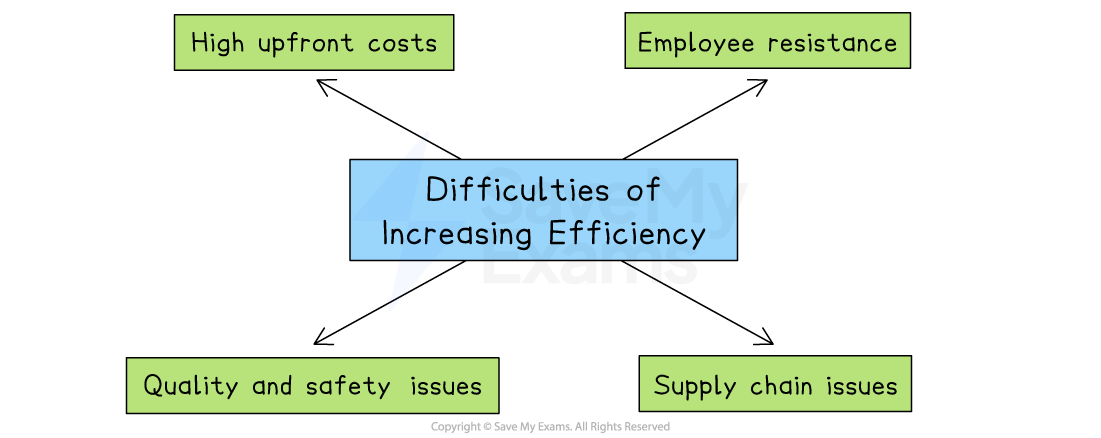

Difficulties increasing efficiency

Improving efficiency in production is not always easy

Difficulties can arise for a range of reasons

Why increasing efficiency can be difficult

Difficulty | Why it makes efficiency gains hard | Example |

|---|---|---|

High upfront cost of new equipment |

|

|

Employee resistance to change |

|

|

Supply chain bottlenecks |

|

|

Quality and safety trade‑offs |

|

|

Efficiency and labour productivity

Labour productivity is the amount of output each worker produces in a given period of time

Higher productivity means the same team turns out more products in the same working hours

Labour productivity is expressed in units and is calculated using the following formula:

Worked Example

Green Man Fisheries prepares a wide range of high-quality seafood dishes that it sells to restaurants. Its most popular product is dressed crab.

Its 12 workers produced 1,404 boxes of dressed crabs in May. In June, the business employed one more worker, and output increased to 1,677 boxes of crabs.

Calculate the difference in labour productivity between May and June.

[3]

Answer:

Step 1: Calculate labour productivity in May

(1)

Step 2: Calculate labour productivity in June

(1)

Step 3: Calculate the difference

(1)

Labour productivity has increased by 12 boxes per worker

Higher labour productivity leads to lower unit costs as long as wage rates remain the same

Worked Example

Each worker at Green Man Fisheries earns £2,000 per month.

Calculate the change in the unit cost of labour between May and June.

[3]

Answer:

Step 1: Calculate labour costs for May and June

(1)

Step 2: Divide labour costs by output for May and June

(1)

Step 3: Calculate the difference

(1)

Unit cost of labour has reduced by £1.59 per box

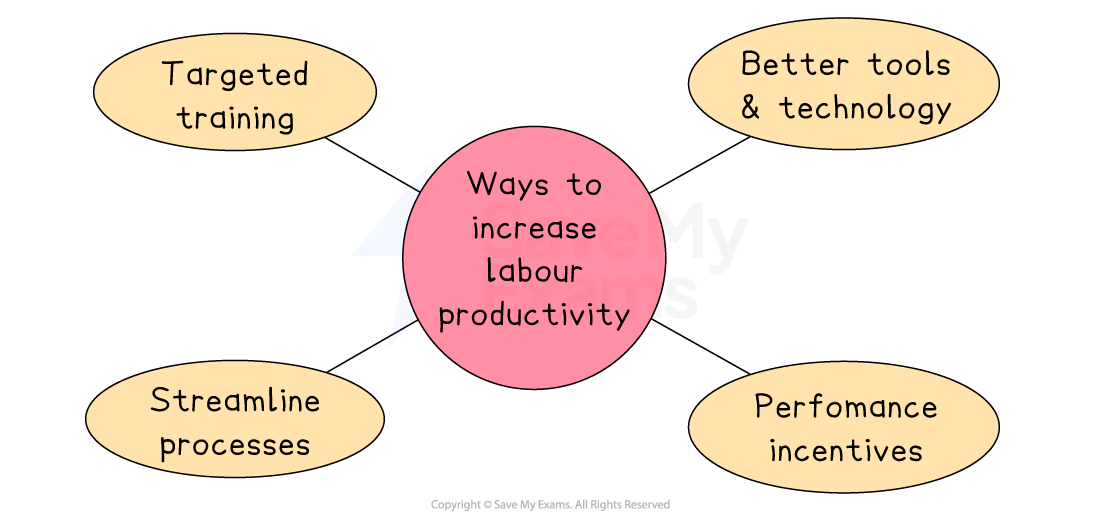

Ways to increase labour productivity

Targeted training

Teach workers faster, safer or multistep techniques so they waste less time and make fewer errors

Better tools and technology

Give employees equipment that speeds up routine tasks

Performance incentives

Link pay or bonuses to clear output targets to encourage extra effort and focus

Streamline processes

Remove wasted steps so workers spend more minutes on value‑adding activity

E.g. Zara reorganised cutting and sewing stages so fabric moves straight to assembly

Difficulties increasing labour productivity

Low morale

Tired, stressed staff work more slowly, are absent more often and make more mistakes, limiting their productivity

Skill shortages

Better tools and methods only help if employees have the right skills

Recruiting or training skilled workers can be slow and expensive

Rigid work rules or union resistance

Employees' contracts may restrict task switching or new performance targets, reducing flexibility and slowing down change

E.g. London Underground’s plans to modernise stations has faced union action, delaying the introduction of multi‑skilled roles and new shift systems

Learning curve for new technology

Installing new software or machines can cut output at first while staff learn and early glitches are fixed

Capital- and labour-intensive production

Capital-intensive production mainly uses machinery and technology in the production of goods and services

Large-scale production of standardised products is likely to be capital-intensive

Manufacturing in developed countries where labour costs are relatively high is likely to be capital intensive

E.g. Car manufacturers such as Ford use robots and other production technology to manufacture vehicles, with supervisors overseeing the quality of output

Labour-intensive production mainly uses physical labour in the production of goods and services

The delivery of services is usually more labour-intensive than manufacturing

In countries where labour costs are low (e.g. Bangladesh), labour-intensive production is common

Small-scale production is likely to be labour-intensive

E.g. UK schools are labour-intensive operations, as teachers plan and deliver lessons and provide pastoral support

Evaluating capital- and labour-intensive production

Type of production | Advantages | Disadvantages |

|---|---|---|

Capital intensive |

|

|

Labour intensive |

|

|

Unlock more, it's free!

Was this revision note helpful?