The Purpose of Operations Management (DP IB Business Management): Revision Note

What is operations management?

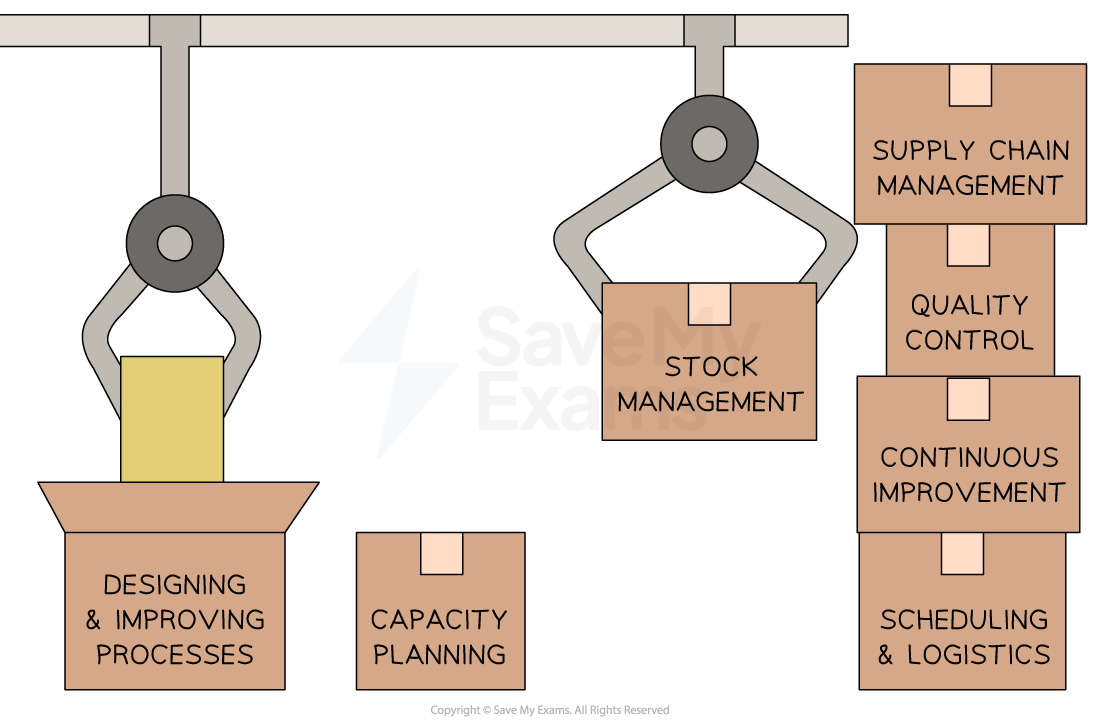

Operations management focuses on designing, controlling and improving the processes used in the production of goods and services

It involves overseeing the entire production process, from acquiring raw materials to delivering the final product/service to customers

The goal of operations management is to ensure that the production process is efficient, cost-effective and meets the desired quality standards

It involves making decisions related to production planning, stock management, resource allocation, scheduling and quality control

Operations management tasks

Designing and improving processes

Operations managers analyse existing processes and find ways to optimise them

They may use tools and techniques such as process mapping and lean production to identify inefficiencies and eliminate waste

Capacity planning

Operations managers determine the production capacity required to meet customer demand

They analyse historical data and market forecasts to ensure that the production resources are adequate to fulfil orders in a timely manner

Stock management

Operations managers are responsible for managing the stock levels of raw materials, work-in-progress and finished goods

They aim to minimise costs while ensuring that enough stock is available to meet customer demand and allow the production process to continue without running out of resources

Supply chain management

Operations managers work closely with suppliers to ensure the timely delivery of raw materials and components

They establish relationships with suppliers, negotiate contracts and monitor supplier performance to ensure a reliable supply chain

Quality control

Operations managers implement quality control measures to ensure that the products/services meet the required quality standards

They develop and enforce quality assurance processes, conduct inspections and address any quality issues that arise

Continuous improvement

Operations managers strive for ongoing improvement in processes, productivity and efficiency

They identify opportunities for innovation, implement new technologies or techniques and encourage a culture of continuous improvement (Kaizen) among employees

Scheduling and logistics

Operations managers develop production schedules and coordinate the flow of materials, equipment and labour to ensure smooth operations

Operations and the production of goods/services

Operations management does not only focus on the production of tangible goods/services in the secondary sector

It is equally applicable in the primary, tertiary and quaternary sectors

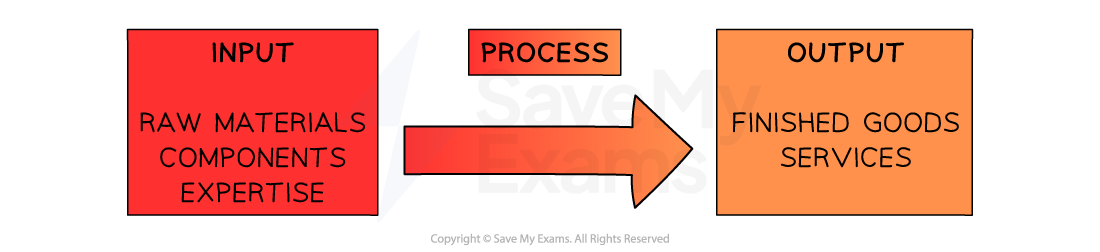

The input-output model is a simple explanation of the operations process

The input-output model

Examples of the input-output model in different sectors

Sector and example | Inputs | Process | Outputs |

|---|---|---|---|

Primary (fishing) |

|

|

|

Secondary (car manufacture) |

|

|

|

Tertiary (restaurant) |

|

|

|

Quaternary (business consultancy) |

|

|

|

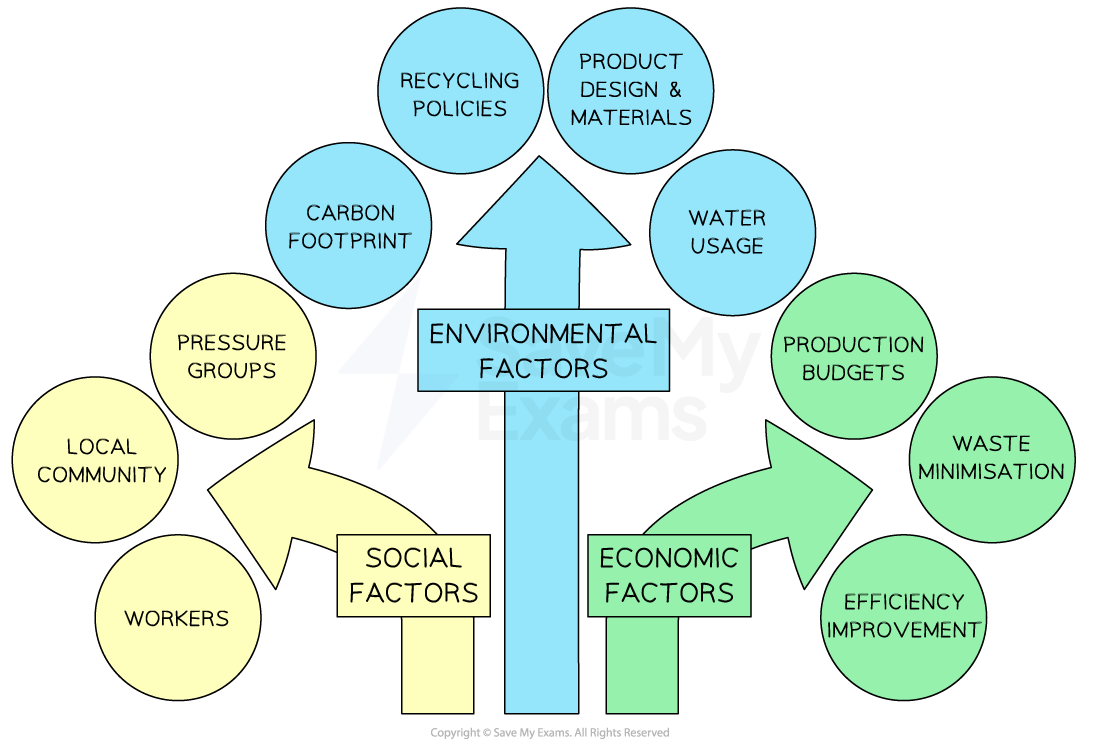

Operations and sustainability

Sustainable operations management involves integrating sustainability practices into all aspects of the operations management process, from sourcing materials to delivering products

There are three elements to sustainable operations management

Sustainable operations management

There are a range of ways to improve sustainability in operations management

Examples of sustainable practices

Green supply chain management

Involves choosing environmentally responsible suppliers, reducing waste, and lowering the business’s carbon footprint across the entire supply chain

Focuses on sustainable sourcing, ethical labour practices and transparent operations

E.g. Patagonia uses sustainable materials like organic cotton and recycled polyester, ensures fair labour practices, and publicly discloses supply chain information

Energy efficiency

Includes adopting energy-saving technologies, optimising equipment, and reducing overall energy consumption

Supports long-term sustainability goals and lowers operational costs

E.g. Danone is committed to using 100% renewable energy and aims to reduce its environmental impact by 2030, with a target of becoming carbon neutral by 2050

Waste reduction and recycling

Involves managing waste effectively, applying lean manufacturing principles, and designing products with minimal material usage and high recyclability

Emphasises the use of eco-friendly, durable materials

E.g. Fairphone produces modular smartphones that allow users to easily replace or upgrade parts, extending device lifespan and reducing electronic waste

Promoting fair labour practices

Ensures safe and healthy working environments, with policies that support wellbeing such as flexible schedules, regular breaks, training access and protective equipment

Can also include benefits that enhance employee satisfaction and work-life balance

E.g. Google offers employees free meals, nap pods, on-site doctors, and pet-friendly offices. It also monitors staff wellbeing and supports hybrid working for greater flexibility

You've read 0 of your 5 free revision notes this week

Unlock more, it's free!

Did this page help you?