Types of Production Methods (DP IB Business Management): Revision Note

An introduction to production methods

Production is the transformation of resources (e.g. raw materials components and processes) into finished goods or services

Goods are physical products, such as bicycles and T-shirts

Services are non-physical items such as hairdressing, tourism and manicures

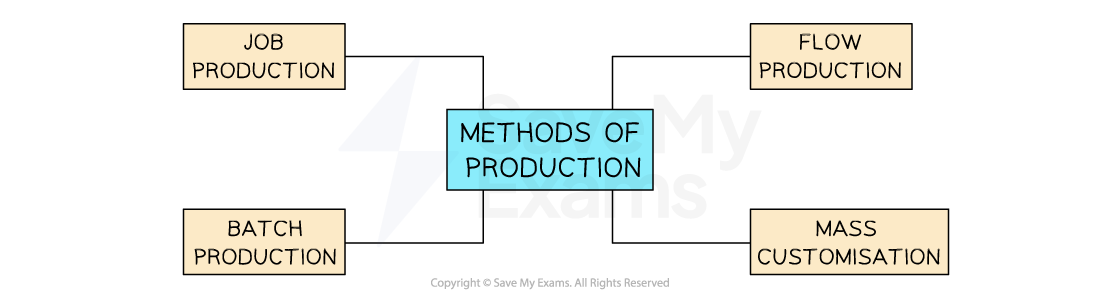

Businesses can organise their production processes in a variety of ways

Methods of production

The method of production used by a business will depend upon a number of factors

The level of output required to be produced

The nature of the product

Whether the product is standardised or customised

The level of automation used in production

Job production

Job production is where products are made to meet the specific requirements of individual customers

Each item is produced separately (a job) and the production process is tailored to the unique specifications of the customer's order

The key characteristics of job production include

Customisation

Each product is customised according to the customer's specific requirements

This allows for personalised goods or services to be created

Low volume

Job production is typically used for unique or specialised products that are not produced in large quantities

Variability

Since each product is made to order, there can be significant variation in the production process and materials used

Skilled labour

Job production often requires skilled labour such as craftsmen or technicians

The manufacturing process may involve intricate tasks or specialised techniques

Longer lead time

Due to the customisation and individual production approach job production usually has longer lead times compared to other production methods

The time required to fulfil each order can vary depending on its complexity and the availability of resources

Evaluation of job production

Advantages | Disadvantages |

|---|---|

|

|

Examples of job production

Furniture made to order, where customers can choose the design, dimensions, materials and finishes | Tailored clothing, such as suits or wedding dresses, where each garment is made to meet the preferences of the individual customer | High-end jewellery pieces, especially those with unique designs or personalised engravings |

|---|---|---|

|  |  |

Batch production

Batch production occurs when products are produced in groups or batches

A certain quantity of products is produced together before moving on to the next batch

Each batch goes through the entire production process, from raw materials to the finished product, before the next batch begins

Batches are usually of a standardised size and composition and follow a certain sequence of operations

Examples of batch-produced goods

Batch production strikes a balance between customisation and cost-effectiveness, making it a suitable production method for industries that deal with diverse product ranges and varying customer needs

Evaluation of batch production

Advantages | Disadvantages |

|---|---|

|

|

Mass/flow production

Flow production occurs when a product is produced in a continuous sequence of operations on a production line

It involves the movement of materials or components through a series of workstations or machines with each workstation performing a specific task or operation

As a product moves along the production line it undergoes a series of operations, such as assembly, testing, packaging or quality control until it is completed

This method is commonly used in industries that produce high volumes of standardised products such as automobiles and consumer electronics

The key characteristics of flow production include:

Division of labour

Different tasks are allocated to different workstations or machines, allowing workers to specialise in a specific task

Standardisation

The manufacture of identical products helps to ensure consistency and a smooth flow of production

Continuous movement

The product moves continuously from one workstation to another, minimising idle time and maximising productivity

High volume

Flow production is suitable for high-volume manufacturing as it enables the efficient production of large quantities of identical or similar products

Automation

Flow production often involves the use of machinery and automated equipment to perform repetitive tasks quickly and accurately

Evaluation of flow production

Advantages | Disadvantages |

|---|---|

|

|

Examiner Tips and Tricks

Carefully consider the needs of the customers to which a business sells when recommending a suitable method of production. Where the selling price is a key driver of consumer demand, flow production (where unit costs are minimised) is likely to be very suitable. Where demand is driven by quality, or where customisation is required, job or batch production are likely to be better choices.

Mass customisation

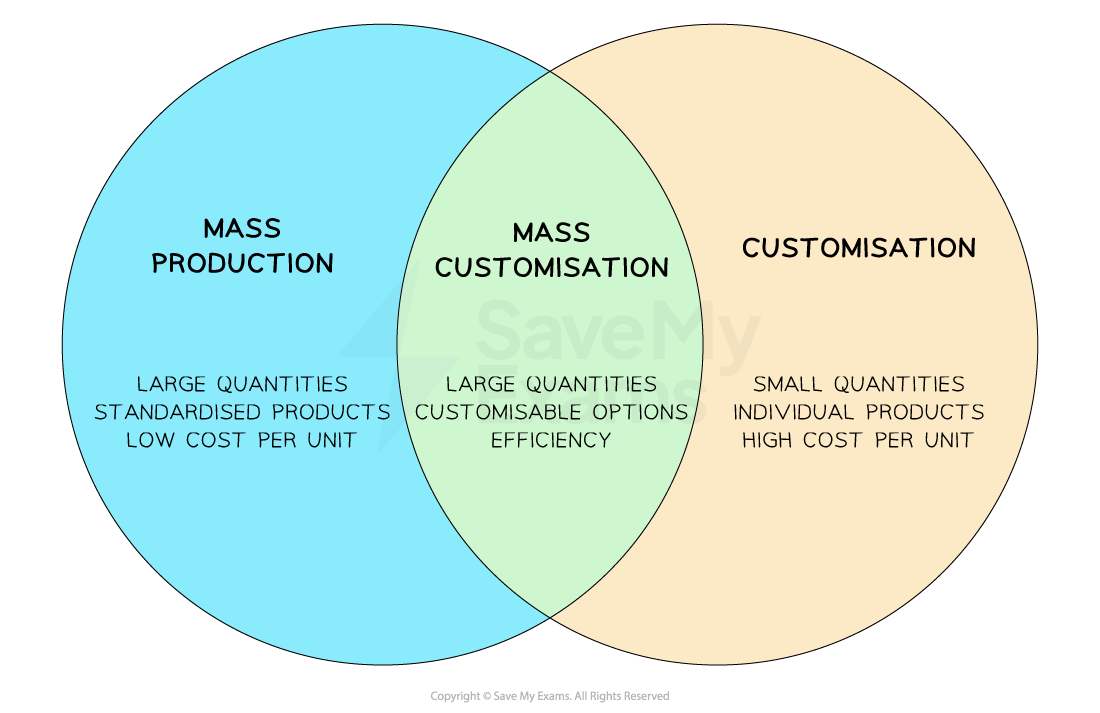

Mass production is usually achieved through flow production and involves the manufacture of large quantities of standardised products

This results in low costs per unit compared to other methods of production

Customisation is usually associated with job production or small-scale batch production

It allows customers to design products from scratch

Mass customisation seeks to bridge this gap

It offers flexibility with a range of customisable options within a standardised production process

It benefits from the low unit costs typically associated with flow production

It uses technology, such as computer-aided design (CAD), flexible manufacturing systems and data analytics to efficiently accommodate customer preferences

Mass customisation

The process of mass customisation typically involves three key elements

Case Study

Mass customisation at Audi

Audi gives customers the chance to design a car that suits their needs and style. Audi’s production process is designed to be fast and flexible, even though each car is different

Choice

First, customers choose from a range of car models

Audi offers different types, such as the Avant, Saloon, Coupé or Sportback.

After choosing the model, customers select a trim level (this means how basic or advanced the car is).

Trim levels are Premium, Premium Plus and Prestige.

Customisation

Next, customers can personalise their car by picking extra features that fit their lifestyle

For example, they might choose to add a towbar, a dashcam or special driving tools

Production

Once the design is final, Audi starts building the car.

Cars are made in Germany using modern machines, including robots and 3D printers

It usually takes between six and twelve weeks to build a customised car.

Mass customisation offers several advantages for both businesses and customers

Customers can obtain products that match their unique preferences and requirements and are likely to be highly satisfied which leads to positive feedback and loyalty

Businesses can adapt to changing market demands effectively by offering a wide range of product variations without the expense of full customisation

By utilising standardised components and processes mass customisation allows businesses to achieve economies of scale, reduce stock costs and improve overall production efficiency

Mass customisation can differentiate a company from competitors, attract new customers and create a perception of high value and innovation

However, mass customisation usually requires heavy capital investment in technology and variable costs tend to be higher than for standardised, mass produced items

You've read 0 of your 5 free revision notes this week

Unlock more, it's free!

Did this page help you?