Syllabus Edition

First teaching 2025

First exams 2027

Labour-Intensive & Capital-Intensive Production (Cambridge (CIE) IGCSE Economics): Revision Note

Exam code: 0455 & 0987

Defining capital-intensive and labour-intensive production

Capital-intensive production occurs when manufacturing relies more heavily on machinery, equipment and technology than human labour

Capital-intensive means that the proportion of machinery costs are higher than any of the other factors of production, including labour

Labour-intensive production occurs when manufacturing relies more heavily on human workers than machines

Labour-intensive means that the proportion of labour costs are higher than the other factors of production, including machinery

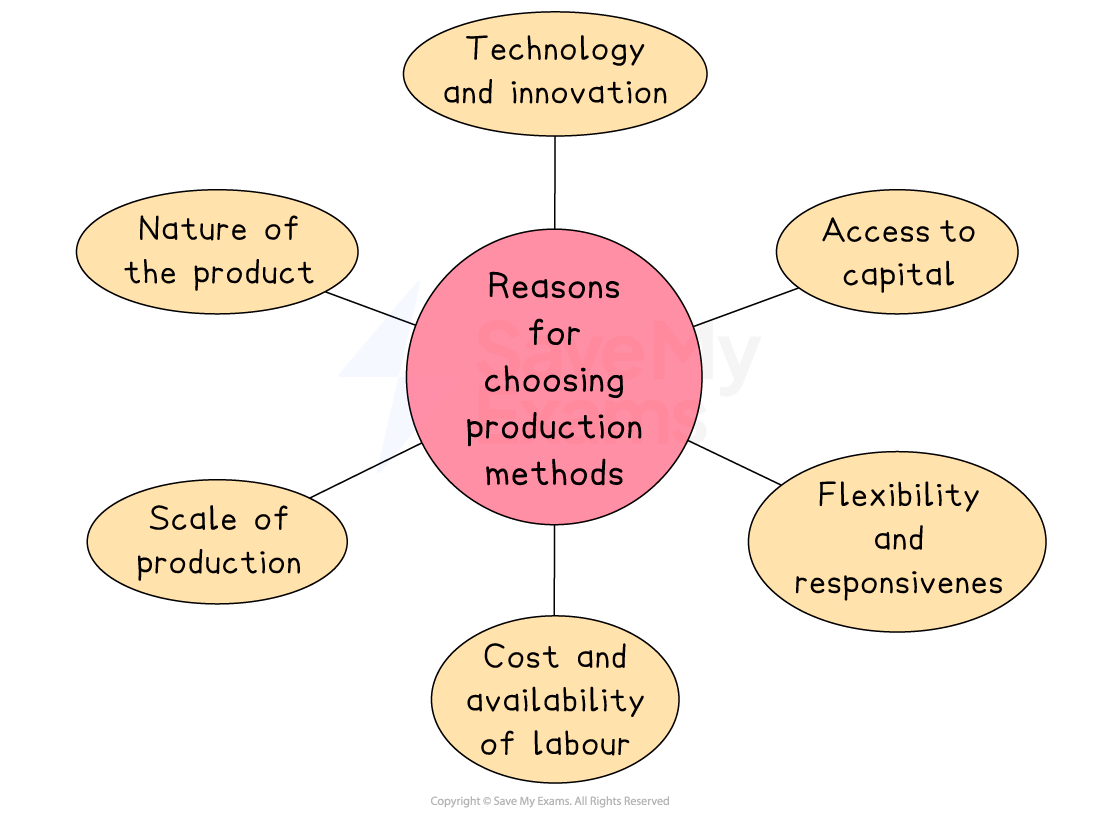

Reasons for adopting the different forms of production

Firms will consider several factors before they decide if their production should be capital-intensive or labour-intensive

Determining factors

1. Nature of the product

Labour-intensive methods are suitable when products require personalisation or craftsmanship

Capital-intensive methods are preferred for standardised, mass-produced goods

2. Scale of production

Large-scale production (e.g., car manufacturing) usually benefits from capital intensity due to economies of scale

Small-scale or batch production (e.g. artisan goods) often relies on labour intensity

3. Cost and availability of labour

In countries with low labour costs, firms may choose labour-intensive production to save money

In high-wage economies, firms often invest in capital to reduce reliance on expensive human labour

4. Access to capital

Firms with greater financial resources are more likely to afford expensive equipment, making capital-intensive production more viable

Small firms may be limited to labour-intensive production due to budget constraints

5. Technology and innovation

In industries where automation and AI can replace manual tasks, capital intensity becomes more attractive

Where technology cannot fully replace human judgement or creativity, labour intensity remains important

6. Flexibility and responsiveness

Labour-intensive systems can be more flexible when customisation or frequent changes are required

Capital-intensive methods are efficient but less adaptable to variation in production needs

The advantages and disadvantages of the different forms of production

Constant improvements to technology and process innovation mean that firms are constantly evaluating the possibilities of moving from labour to capital-intensive production

Evaluating labour-intensive production

Advantages | Disadvantages |

|---|---|

|

|

Many industries are gradually replacing labour with capital when it makes financial sense to do so

As wages rise in a country, more labour will be replaced by capital (machinery)

Evaluating capital-intensive production

Advantage | Disadvantages |

|---|---|

|

|

Case Study

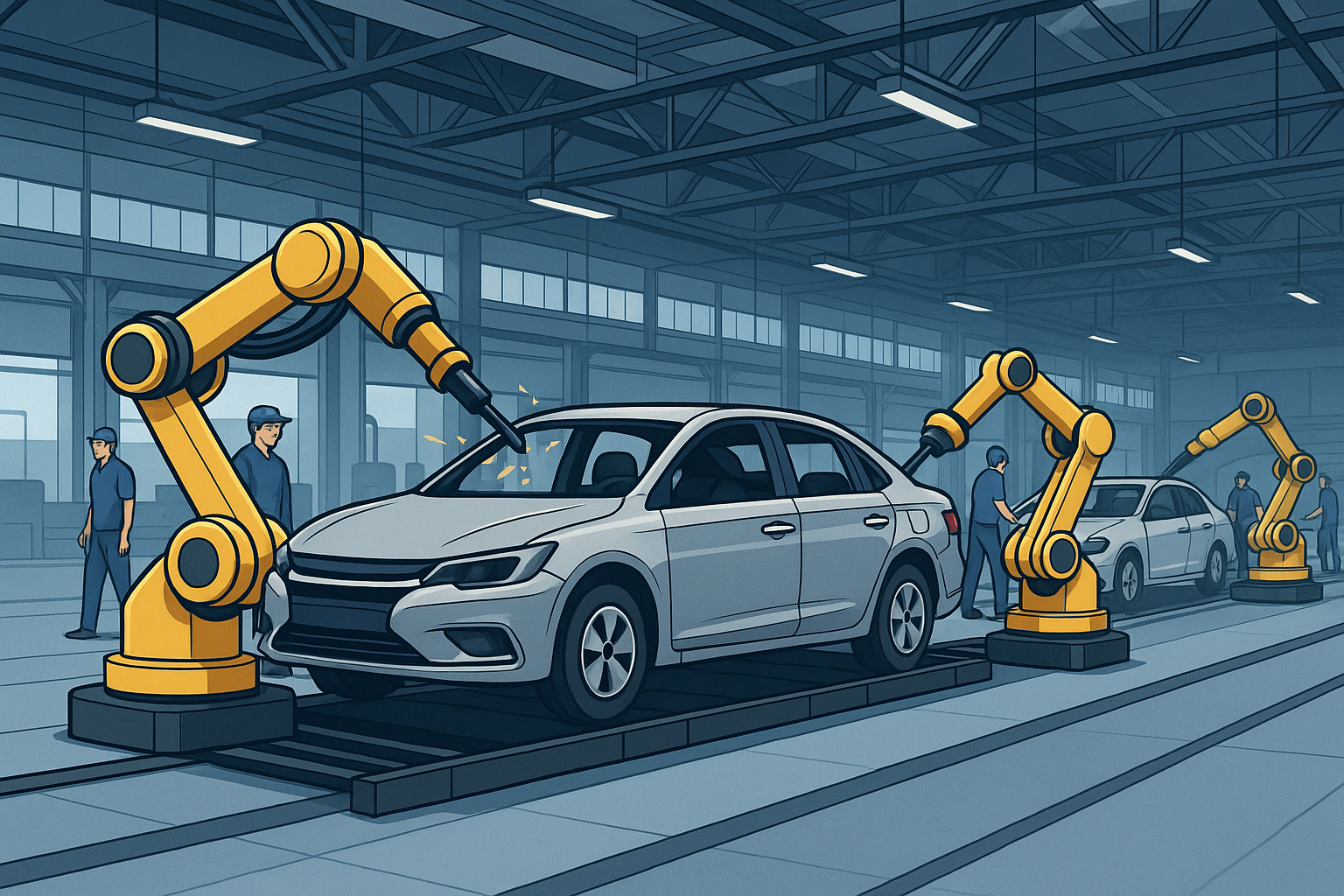

Toyota Increases Capital-Intensive Production

In 2025, Toyota, one of the world’s largest car manufacturers, announced it would expand the use of robotics and automation in its production plants in Japan and the United States. The company’s decision was driven by a combination of factors, including rising labour costs, a tight labour market, and advances in robotic efficiency and AI.

Why Toyota Is Shifting Towards Capital-Intensive Production

Rising wages and labour shortages

Japan’s ageing population and the tight labour market have made it harder to recruit skilled factory workers.

This has increased wage pressure and prompted Toyota to seek alternatives through automation

Improved robotics and AI

Toyota has developed more advanced robots that can now perform more precise and complex tasks that previously required human input

These machines operate 24/7 with minimal downtime, improving output and consistency

Long-term cost efficiency

While installing advanced robotics is expensive, Toyota views it as a long-term investment that will reduce labour costs, errors and downtime, leading to lower average costs per unit over time

Maintaining global competitiveness

As global rivals increasingly adopt automation, Toyota's shift helps ensure it remains efficient, competitive, and able to respond to global demand fluctuations

Outcome

Toyota’s investment in automation increases fixed costs, but helps reduce variable labour costs. By spreading costs over greater output, it improves efficiency and raises profits through lower average costs and consistent production

Unlock more, it's free!

Was this revision note helpful?