Extraction of Metals (SQA National 5 Chemistry): Revision Note

Exam code: X813 75

Methods of metal extraction

Most metals are found in the Earth's crust not as pure elements, but chemically bonded to other elements in compounds

A rock that contains enough of a metal compound to be worth extracting is called an ore

Extraction of metals

To get the pure metal, it must be extracted from its ore

In the ore, the metal exists as a positive ion

The extraction of a metal from its ore is always a reduction reaction

The positive metal ions must gain electrons to become neutral metal atoms

For example:

Al3+ + 3e- → Al

The method used for extraction depends entirely on the metal's reactivity

Very reactive metals form very stable compounds, which are difficult to break down, and therefore require more energy to extract

Extraction by heat

This method is suitable for the least reactive metals, such as silver, gold, and mercury

The compounds of these metals are unstable and easily decompose

Heating the ore provides enough energy to break the bonds and release the metal

For example, the extraction of silver from silver oxide:

silver oxide → silver + oxygen

2Ag2O (s) → 4Ag (s) + O2 (g)

Each silver ion (Ag+) gains one electron:

Ag+ + e- → Ag

Extraction by heating with carbon (or carbon monoxide)

This method is suitable for metals in the middle of the electrochemical series, such as copper, lead, tin, iron, and zinc

These metals are too reactive to be extracted by heat alone

They must be heated in a furnace with a reducing agent

A reducing agent is a substance that removes oxygen

Carbon (in the form of coke) or carbon monoxide (CO) are commonly used reducing agents

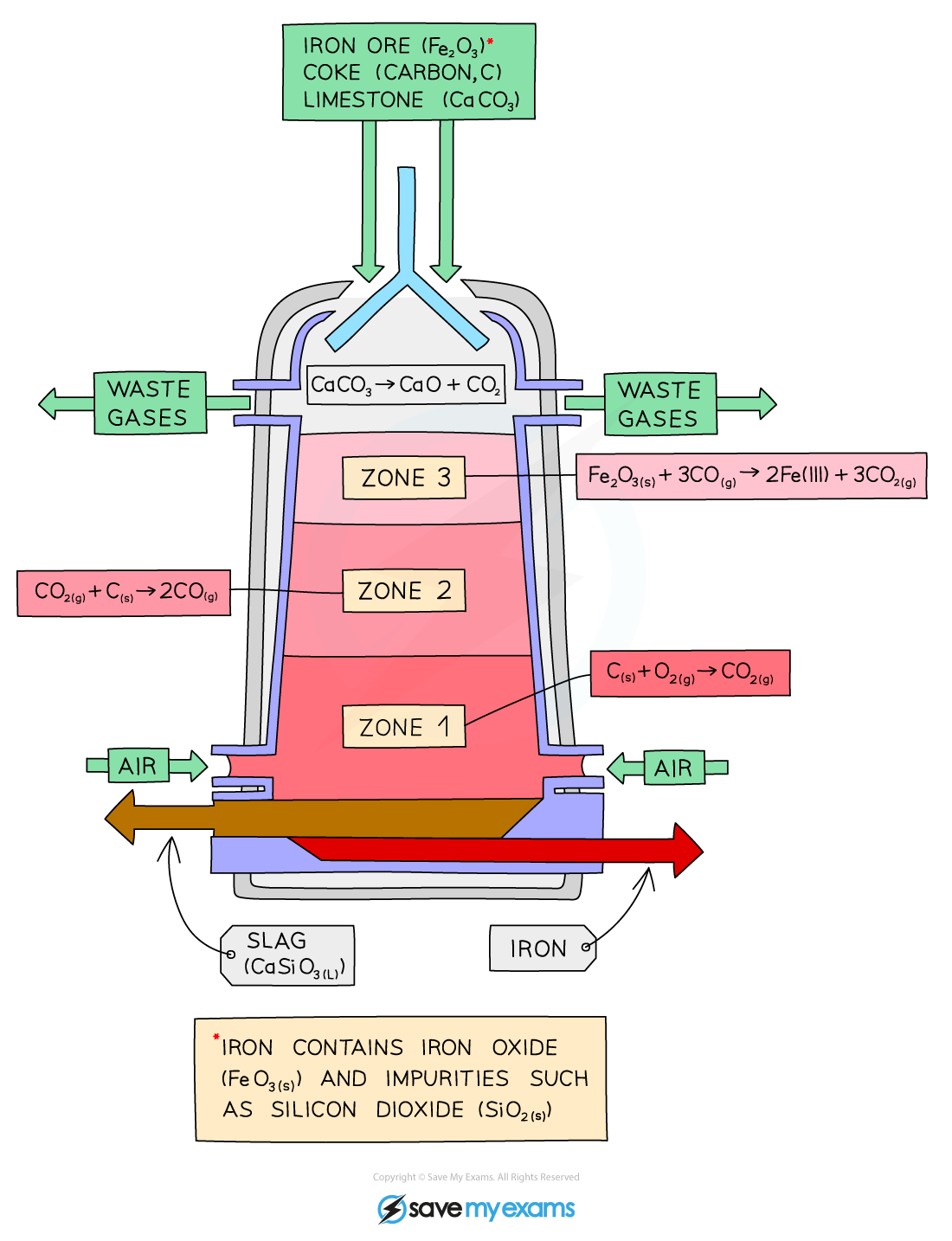

For example, the extraction of iron in a blast furnace:

iron(III) oxide + carbon monoxide → iron + carbon dioxide

Fe2O3 (s) + 3CO (g) → 2Fe (l) + 3CO2 (g)

Each iron(III) ion (Fe3+) gains three electrons:

Fe3+ + 3e- → Fe

The blast furnace

Extraction by electrolysis

This method is suitable for the most reactive metals, such as potassium, sodium, calcium, magnesium, and aluminium

These metals form very stable compounds that cannot be reduced by carbon

Electrolysis, which uses a powerful direct electric current to break down the compound, is required

This process is very expensive due to the high energy demand

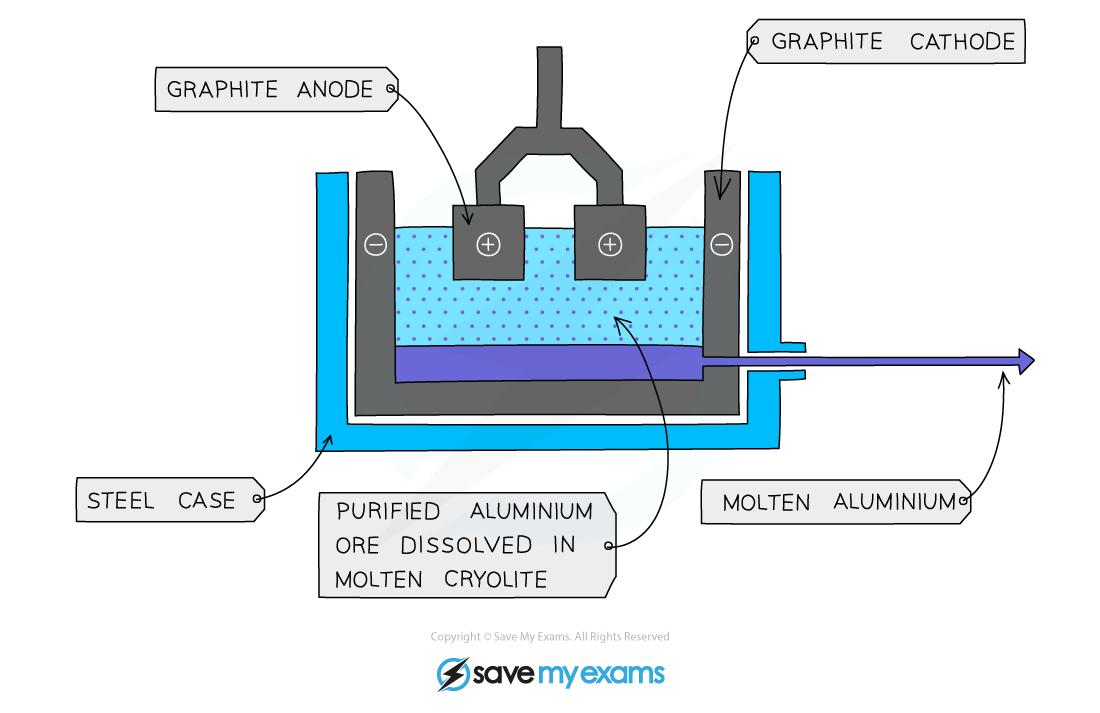

For example, the extraction of aluminium from aluminium oxide:

The molten aluminium ore is decomposed by electricity

The positive aluminium ions (Al3+) are attracted to the negative electrode

At the negative electrode, each aluminium ion gains three electrons to become a neutral aluminium atom:

Al3+ + 3e- → Al

Extraction of aluminium

Extraction summary

Position in the electrochemical series | Example metals | Method of extraction |

|---|---|---|

High (most reactive) | K, Na, Ca, Mg, Al | Electrolysis |

Middle | Zn, Fe, Pb, Cu | Heating with carbon / carbon monoxide |

Low (least reactive) | Ag, Au, Hg | Heat alone |

Unlock more, it's free!

Was this revision note helpful?