Haber & Ostwald Processes (SQA National 5 Chemistry): Revision Note

Exam code: X813 75

The Haber process

The Haber process is an industrial process

It is used to manufacture the ammonia (NH3) required for fertiliser production

The reaction

The process is a reversible reaction between nitrogen gas (from the air) and hydrogen gas:

nitrogen + hydrogen ⇌ ammonia

N2 (g) + 3H2 (g) ⇌ 2NH3 (g)

The ⇌ symbol shows that the reaction is reversible

This means that the reaction can go in both directions

The forward direction makes ammonia

The backward direction breaks ammonia down

The conditions

Choosing the right conditions for the Haber process involves a compromise between:

The rate / speed of the reaction

The amount of product you get (the yield)

Temperature

At low temperatures:

The forward reaction is favoured

This gives a high yield of ammonia

However, the reaction is too slow to be economical

At high temperatures:

The rate of reaction increases

This is because particles have more energy, leading to more frequent and successful collisions

However, the backward reaction becomes more dominant

This leads to a low yield of ammonia

This means that a compromise temperature is used to get a reasonable rate and a reasonable yield

Catalyst

An iron catalyst is used to increase the rate of reaction

The catalyst speeds up both the forward and backward reactions equally

This allows the process to become fast enough to be economical at the compromise temperature

Examiner Tips and Tricks

You must know the catalyst for this process

Remember: Making fertilisers is a tough, industrial job, and you need a tough metal like iron to get it done

The Ostwald process

The Ostwald process is the industrial method for producing the nitric acid (HNO3) needed to make fertilisers

The reaction

Ammonia, made in the Haber process, is the essential starting material

In the Ostwald process:

Ammonia reacts with oxygen (from the air)

Water is also used in the process

The final product is nitric acid

Examiner Tips and Tricks

The Ostwald process involves several steps, but you only need to know:

The overall reactants: ammonia, oxygen and water

The final product: nitric acid

The catalyst

A platinum catalyst is used to speed up the reaction between ammonia and oxygen

Like all catalysts, the platinum is not used up and can be recovered at the end of the reaction

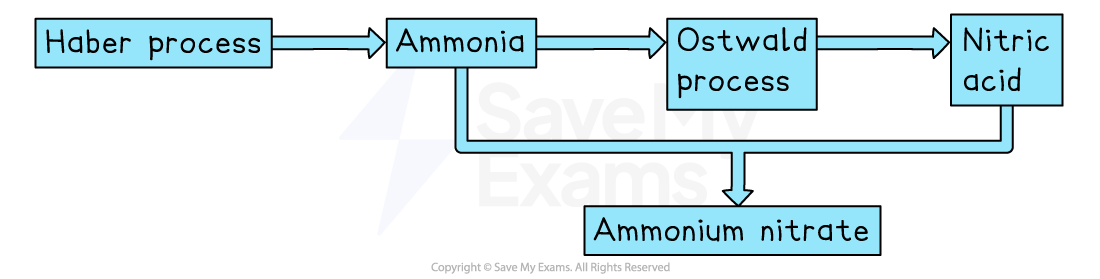

Linking the processes

The Haber and Ostwald processes are linked together in the production of ammonium nitrate, a key fertiliser

The Haber process produces ammonia

The Ostwald process uses some of the ammonia to produce nitric acid

Ammonia (from the Haber process) and nitric acid (from the Ostwald process) are used to make ammonium nitrate

Examiner Tips and Tricks

You must know the catalysts for both processes. Don't get them mixed up

Haber process = iron (Fe)

Ostwald process = platinum (Pt)

Unlock more, it's free!

Was this revision note helpful?